In America, where dentists are turning to digital technology to provide better services for patients, refrigerator-sized machines created by Israeli startup Nexa3D print dental retainers, night guards and other accessories that used to require multiple molds of patients’ teeth and hours of lab work. The new method is faster and often results in better-fitting products.

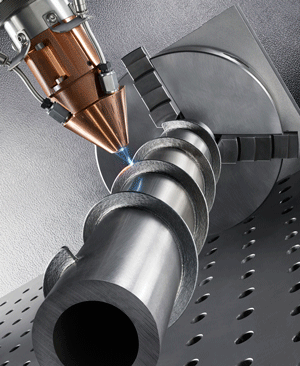

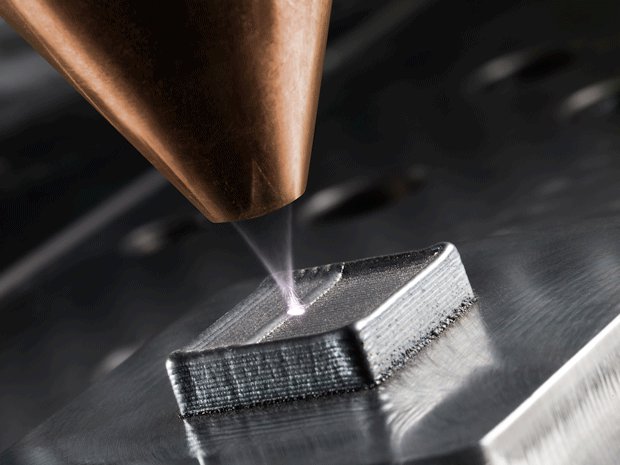

Nexa3D’s NXE400 ultra-fast printer increases productivity by 20 times compared to competitors and is set to transform 3D printing from a tool for prototype designers to a fully fledged industrial machine operating at production scale. The step change promises to transform the 3D printing industry in the same way broadband internet replaced dial-up.

Dentistry is just a small part of Nexa3D’s business, which spans carmakers, entertainment and industry. In a matter of hours, Nexa3D’s printers in factories around the world, aided by innovative software, transform soft resin into car parts, protective face shields, drones and countless other objects.

When BMW opened its Additive Manufacturing Campus in June 2020, a NXE400 was prominently on display

Additive manufacturing is already an integral part of our worldwide production system today, and established in our digitalisation strategy,” said BMW’s Milan Nedeljković. “In the future, new technologies of this kind will shorten production times even further and allow us to benefit even more fully from the potential of toolless manufacturing.”

The sector is becoming a hot target for investors. Desktop Metal, which specializes in 3D printing of metal and composite parts, went public via a $2.5 billion SPAC in December and is now valued at more than $5 billion. Two more companies, 3D Hubs and EnvisionTEC, were acquired in January 2021.

German manufacturing giant Siemens signed a partnership deal with Nexa3D in September, and will soon begin integrating the printers into its factories.

“We are very pleased to join forces with Nexa3D and together unleash the power and potential of our products to create more resilient and sustainable supply chains,” said Tim Bell, head of Additive Manufacturing at Siemens.

source :https://www.timesofisrael.com/spotlight/israeli-startup-takes-3d-printing-out-of-the-workshop-and-into-the-factory/